Sep. 11, 2020

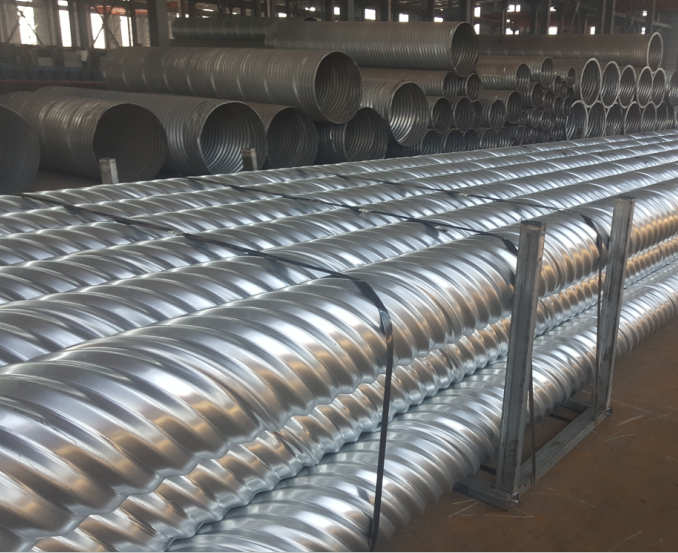

Corrugated steel structure:

Corrugated steel structure is a structure in which a certain thickness of steel plate is corrugated to increase its rigidity; the corrugated formed on a flat plate, with the increase of the bending depth, its rigidity can increase by 5 to 10 times. Steel corrugated pipe culvert is a form of corrugated steel structure. It adopts corrugated pipe or a culvert formed by connecting and assembling corrugated arc-shaped plates. Due to the existence of axial corrugations, it can give full play to the advantages of force. , It can distribute the stress and strain caused by the load in the axial and radial directions at the same time, can disperse the stress concentration of the load to a greater extent, and give better play to the advantages of the steel structure, with excellent force characteristics.

Structural advantages:

Rolling a flat steel plate of the same thickness into a corrugated steel plate with a corrugated shape has a significant increase in the moment of inertia and a significant increase in load resistance. Therefore, the steel bellows culvert can better resist the static load of the soil and the dynamic load of the driving vehicle. , To ensure safety after opening to traffic, and its safety factor is greatly increased.

As a typical spatial structure, corrugated steel arch culvert has the unique good ductility of steel structure, high tensile, compressive, and shear strength, small structural section, light weight, and fast construction speed. , It can provide features such as large-span structure. Compared with traditional reinforced concrete culverts and small-span bridges, corrugated steel plate bridges and culverts have high strength, good durability, good mechanical performance, strong deformation resistance, simple construction, short construction period, It is beautiful and does not require maintenance after completion. It is environmentally friendly and improves the uneven settlement of special foundation structures such as soft soil, expansive soil, collapsible loess, etc., and reduces the phenomenon of bridge head jumping and culvert jumping, and It has obvious advantages in reducing project cost.

Corrugated steel pipe culvert is more and more widely used. In addition to the advantages of the above structure, the flexibility of the opening treatment is also one of the main reasons why the structure is favored by design units. At present, the processing methods of corrugated steel culverts are mainly as follows:

Corrugated Steel Arch Culvert

1. With a cut bamboo hole, the slope is consistent with the roadbed, no other treatment is required. (This method is mostly used abroad)

2. For the corrugated pipe culvert with extended opening, the culvert extends out of the roadbed without further treatment. (Used for smaller diameter bellows, more in foreign countries)

3. Large-span corrugated steel box culvert with steel sheet pile end walls (this method is often used for large-span culverts with shorter culvert lengths)

4. Large-span corrugated steel arch culvert with concrete end walls (this method is mostly used for large-span culverts)

5. The mortar opening of the eight-character wall or the one-character wall (the conventional treatment method of culvert openings in my country)

6. Treatment of concrete openings with multiple functions (such as passages and culverts)

7. The corrugated steel opening of the eight-shaped wall or the one-shaped wall (new type of opening technology) is of uniform material with the corrugated steel pipe, with good consistency and easy construction.

Other Blog

Highway Construction

Highway Construction  Mine Projection

Mine Projection  Municipal Engineering

Municipal Engineering  Irrigation Engineering

Irrigation Engineering  Railway Construction Projection

Railway Construction Projection  Other Application

Other Application Do you need a project solution?

With first-class products and services, and make greater contributions